SEOAM Workholding Solutions

High Quality Vises and ChucksKenyeri Engineering & Manufacturing is an authorized US distributor of SEOAM products. We work extensively with SEOAM and are able to solve technical problems for our customers without fail. We have the knowledge to sell the solution, which means making the chuck work for you.

We can help you with:

- Power Chucks and Hydraulic Cylinders

- Manual Chucks

- Power Vises

- Electromagnetic Chucks

- Curvic Couplings and Gears

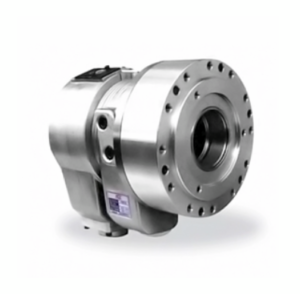

Power Chucks and Hydraulic Cylinders

SEOAM provides a world-class high-quality high-precision power chuck series characterized by high gripping force, high speed with light weight.

More information:

- Drawings and Manuals – Big Bore Chucks

- Product Catalog

- User Manual

SEOAM produces a high quality, high precision series of hydraulic cylinders designed to realize high-rotating speeds while maintaining a compact, slim, light-weight design.

More information:

- Drawings and Manuals – Big Bore Cylinders

- Product Catalog

- User Manual

Special Chucks

SEOAM manufacturers a series of reliable, high precision, high durability special chucks.

More information:

Manual Chucks

SEOAM manufacturers a series of reliable, high precision, high durability manual chucks.

More information:

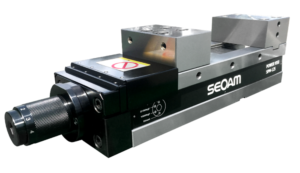

Power Vises

POWER VISES

SEOAM manufacturers a series of hardened carbon steel power vises designed to work with milling machines, CNC machines centers, etc.

More information:

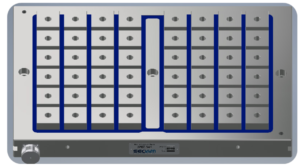

Electromagnetic Chucks

SEOAM produces electromagnetic chucks are safe and have precise machining with a strong clamping force. The magnetic level of the chuck can be adjusted from 1 to 8 steps. These chucks minimize damage to the workpiece by clamping it with electro-magnetic force. Since there is almost no residual magnetic force, it can be easier for material separation and chip removal.

More information:

Curvic Couplings and Gears

Curvic coupling is a key part of indexing devices. It secures operation accuracy in turret devices of CNC lathes, machining centers and other indexing devices.

- Standardized Models

- Rigidity and Abrasion Resistance

- Improved Restoration Division Accuracy

- Precise Self-Centering & Compatibility

- Customized Production

More information:

SEOAM Gears are high quality, high reliability, low noise and low vibration.

- High Quality — Secure quality management system implemented throughout the entire manufacturing process from materials to heat treatment to grinding processes.

- High Reliability — Gears are manufactured with cutting edge machines to achieve consistent high quality and durability.

- Low Noise and Low Vibration — Gears applied crowning and profile-modification allow for use in high-speed rotation.

Large-sized gear reducers for ships and industrial purposes are also available.

More information:

Kenyeri Engineering & Manufacturing is a US Authorized SEOAM Distributor.

SEOAM History Highlights

SEOAM, based in South Korea, provides chucks, curvic couplings, hydraulic cylinders, gears, and power vises to a variety of industries in a number of countries.

The company was established in 1978 as the Hwacheon Gear Company, Ltd., when it was spun off from the Hwacheon Machining Tools Company, Ltd. — which itself was founded in 1952. The company sold its wares locally until 1990 when it began exporting to Japan.

The company achieved ISO 9001 Certification in 1998 and in 1999 started shipping to Germany.

In 2000 Hwacheon Gear Company officially changed its name to SEOAM Machinery Company, Ltd.

SEOAM started exporting to the United States and China in 2002. In 2003 they began shipping to Taiwan.

In 2006 SEOAM was award 5 patents for centrifugal compensating power chucks for pallet changing devices, and in 2011 SEOAM was listed on KOSDAQ, the South Korean stock exchange.