Hanwha Collaborative Robot Benefits

Benefits | Industries | Applications | HCR-3A | HCR-5A | HCR-12A

HCR

Collaborative Robot

Hanwha collaborative robot HCR series is easy and simple in any application.

Automation is no longer difficult. The collaborative robot HCR is easy to control and is flexible in responding to changes in production layout, effectively cutting investment cost and operating expenses.

It not only automates manual work but also provides a safe and convenient work environment.

Easy

One-day training is enough to be a robot operator

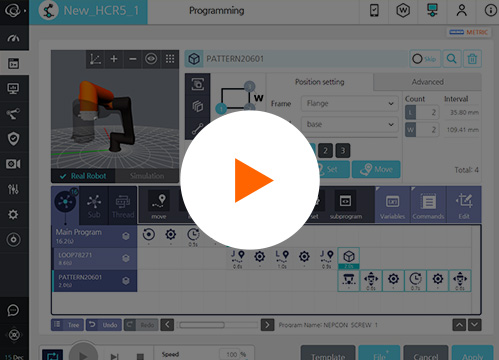

HCR’s intuitive graphical user interface allows you to program the robot after several dozen minutes of learning. HCR is easy to program, thanks to its icon-based GUI, and the timeline basis programming allows users to intuitively monitor the workflow.

In a simpler way, the user grasps the robot and directly teaches the waypoint or the motion path to the robot.

Flexible

Fast set-up enables flexible change of manufacturing

Simple

HCR is easily connected with automation peripherals

As collaborative robots gain widespread adoption across various industries, the demand for peripheral robotic accessories will grow in tandem. Hanwha recognizes this and the vital importance towards fast and easy deployment of robotics solutions.

In order to facilitate such robot system integrations, Hanwha provides pre-compatibilities with peripherals such as vision and EOATs, including grippers and torque sensors.

Hanwha Robotics always welcomes industrial partners to work with.

Safe

HCR collaborates with employees

It is safe to install the robot right next to the operator as the robot stops when it detects an external collision. (ISO 13849-1 Category 3 PLd)

Friendly

HCR is designed for user’s convenience

The LED light on wrist lets you see at a glance the status of the robot. Tool I/O and EtherCAT port at the end of the robot eliminates the need for complicated cabling.

HCR’s robot software, Rodi, has pre-compatibility with major vision vendors, allowing users to easily integrate robot and vision systems.

In particular, Rodi has additional commands to make it easier to set up for tasks such as loading, palletizing, and conveyor trekking, which are frequently used in robotic applications and are cumbersome to program.

FAQ

Here you can find answers to frequently asked questions.

Downloads

Here you can find product-related downloads.

Contact Us

Submit any product-related question you may have.

Have Questions about how Hanwha Collaborative Robots can Work for Your Business?

Contact the Hanwha Collaborative Robots experts at Kenyeri Engineering to learn more!